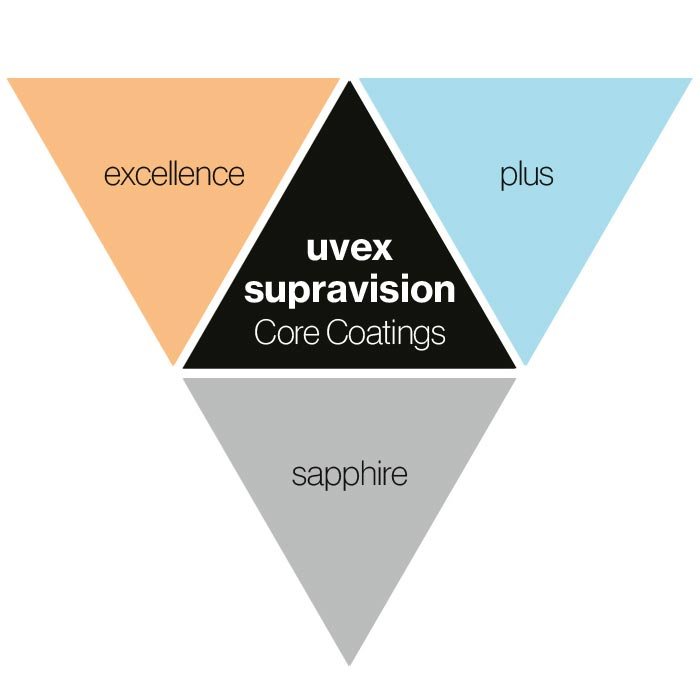

- excellent combination of different coatings on the same lens

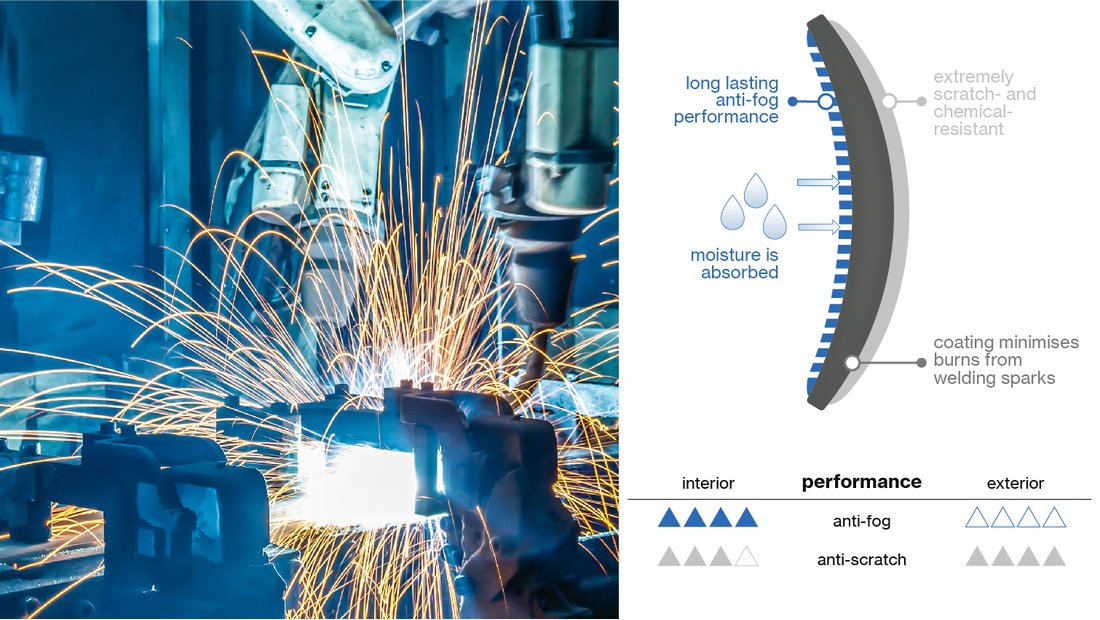

- unique dual-action permanent anti-fog coating on the inside

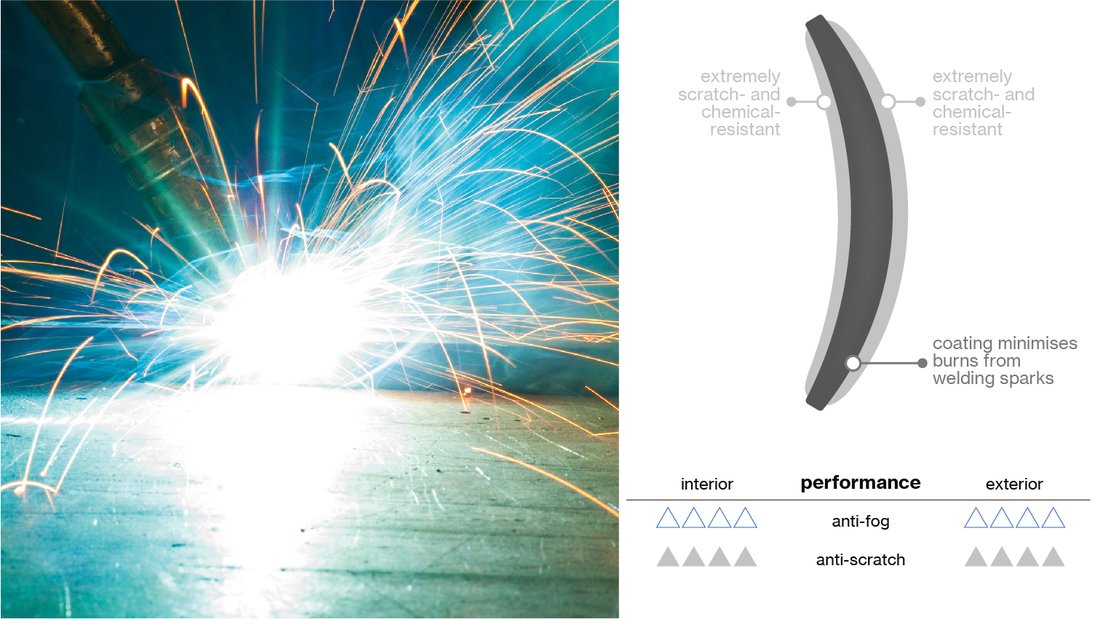

- extremely scratch-resistant and chemical-resistant on the outside of the lens with non-stick, easy-to-clean technology

- long-lasting anti-fog performance on the inside

- anti-fog performance will not diminish even after repeated cleaning

- suitable for a wide range of workplaces

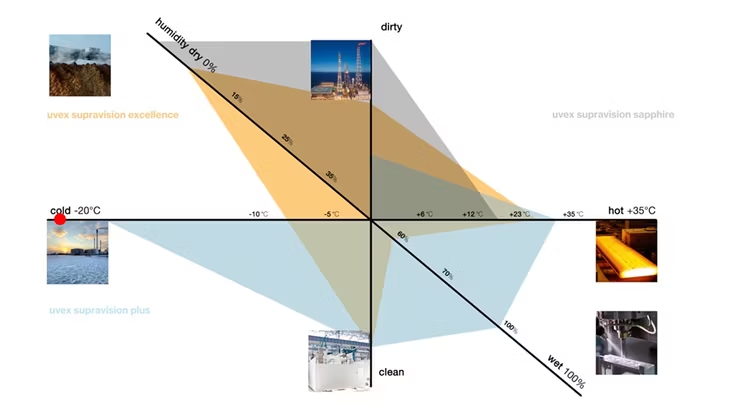

Finding the right coating

Special working conditions also require special coatings for the lenses of safety eyewear.

The adjacent video demonstrates how to determine which uvex supravision Core Coating is right for you.

The decisive parameters for choosing the right coating are the prevailing temperature, humidity and level of contamination at the workplace.

uvex supravision special coatings

Interior:

- durable, permanent anti-fog performance

- coating forms a thin veil of water in humid environments without impairing vision

Exterior:

- extremely scratch-resistant, chemical-resistant and easy to clean

Area of application:

- prolonged exposure to high risk of fogging and dirt

A question of safety

Fogged-up or scratched lenses prevent clear vision through your safety eyewear. This may quickly become dangerous. This video answers the question of what you can do about it.

If you want to effectively prevent your safety eyewear from becoming fogged-up or scratched, then make sure that you buy the right coating to fit the requirements of your job.